A groundbreaking advancement in wearable robotics is emerging from South Korea, promising to transform everyday clothing into powerful assistive devices. Researchers at the Korea Institute of Machinery and Materials (KIMM) have developed a method for mass-producing ultra-thin “fabric muscles” that mimic the flexing and lifting capabilities of human tissue. This innovation could revolutionize how wearable robots enhance mobility, reduce physical strain, and support a wide range of users—from factory workers to patients recovering from injury.

**The Innovation Behind Fabric Muscles**

At the heart of this breakthrough is an automated weaving system devised by KIMM scientists that spins coils of shape-memory alloy into yarns even thinner than a human hair. These coils possess the remarkable ability to contract and expand in response to electrical signals, much like natural muscles. Despite weighing less than half an ounce, a single strand of this material can lift approximately 33 pounds, offering an ideal combination of lightness, flexibility, and strength to power wearable robotics.

Traditional wearable robots typically rely on bulky motors or pneumatic systems that can be heavy, noisy, and costly. Such designs often restrict a wearer’s natural movement, limiting their practicality for daily activities. KIMM’s approach innovates by replacing the metal core used in earlier coil designs with natural fibers. This change allows the yarn to stretch more freely while maintaining its powerful actuation capability. Furthermore, the upgraded automated weaving system enables continuous production of these fabric muscles, making large-scale manufacturing feasible and efficient.

**Wearable Robots That Move With You**

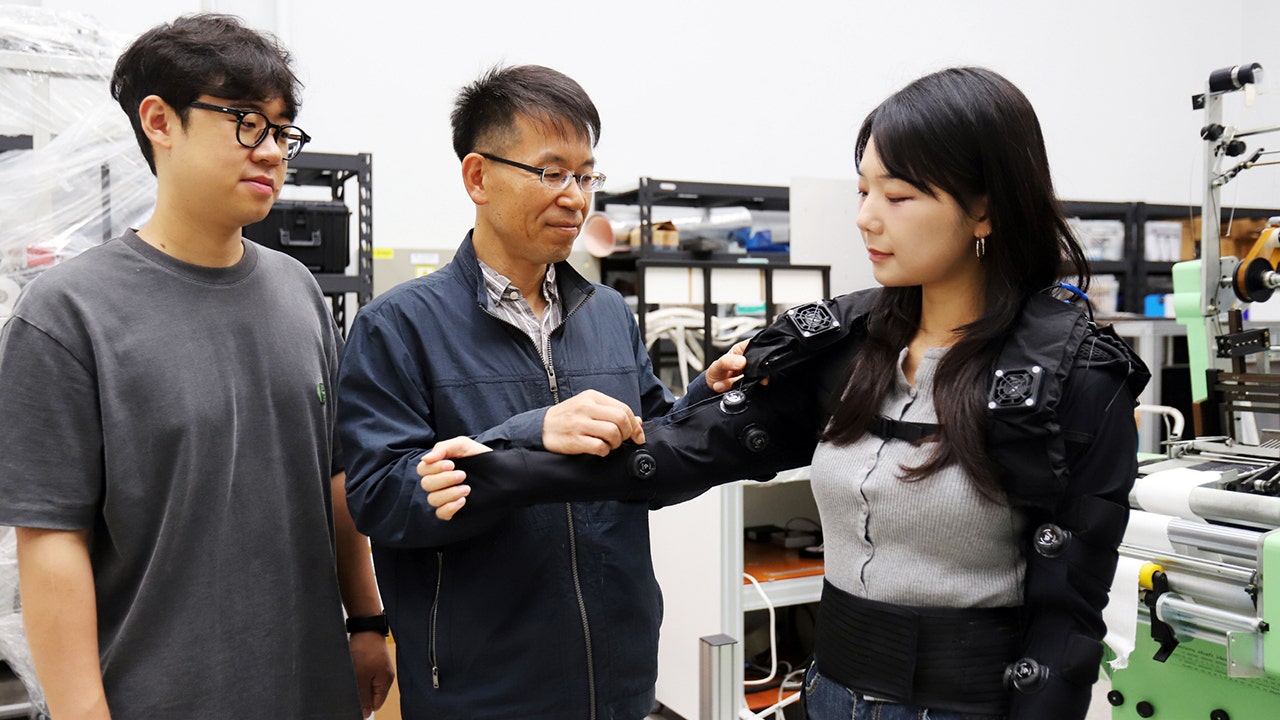

The practical outcome of this technology is a lightweight actuator that moves seamlessly with the human body. It can support multiple joints simultaneously—like the shoulders, elbows, and waist—without impeding natural motion. Leveraging this fabric muscle technology, the KIMM team successfully built the world’s first clothing-type wearable robot that weighs less than 4.5 pounds. In tests, this prototype reduced muscle effort by more than 40% during repetitive tasks, demonstrating its potential to alleviate physical strain.

KIMM also developed a smaller model specifically designed to support the shoulders, weighing only about 1.8 pounds. This version underwent hospital trials at Seoul National University Hospital, where patients suffering from muscle weakness experienced an improvement in shoulder mobility of over 57%. These encouraging results suggest that fabric muscles can extend far beyond industrial applications, offering life-changing assistance to individuals with mobility challenges and helping restore independence and quality of life.

**Potential Applications in Everyday Life and Industry**

The implications of fabric muscle technology are vast and could soon become part of daily routines. Imagine wearing a jacket that silently assists you in lifting heavy groceries or a work shirt that reduces fatigue during long shifts. For individuals undergoing rehabilitation, such clothing could provide continuous, gentle support that eases movement and reduces pain. Healthcare workers, construction personnel, logistics employees, and others engaged in physically demanding jobs might face fewer injuries and enjoy enhanced safety, thanks to the reduced strain and fatigue these wearable robots offer.

As fabric muscle technology evolves, it may blur the lines between clothing and robotics, creating garments that are not only comfortable but also actively supportive. This could redefine how we think about wearable devices and open new avenues for integrating assistive technology into everyday apparel.

**An Industry-First and a Glimpse Into the Future**

KIMM’s achievement marks a significant milestone in wearable robotics. By integrating mechanical strength into soft, flexible materials, engineers are bridging the gap between robotic power and human comfort—a longstanding challenge in the field. The successful automation of fabric muscle production paves the way for widespread adoption, from manufacturing floors and healthcare settings to homes and public spaces.

This development also aligns with broader trends in robotics and artificial intelligence, where machines are becoming more human-like in their interactions and capabilities. For example, other recent innovations include AI-powered humanoid robots designed for industrial use, highlighting the rapid progress in making robots more adaptable and responsive to human needs.

**Looking Ahead: Would You Wear Robotic Clothing?**

As fabric muscle technology advances, the prospect of clothing that enhances strength, reduces effort, and supports natural movement becomes increasingly tangible. Such garments could offer profound benefits—helping people perform everyday tasks with less fatigue, aiding recovery from injuries, and enabling workers to stay safe and productive.

The question remains: would you be willing to incorporate robotic clothing into your daily life if it meant greater freedom and less physical strain? This emerging technology raises exciting possibilities and invites us to reconsider the role of clothing as not just protection or fashion but as an active partner in our physical well-being